Tubular Blancher – Vegetables, Blanching, Water-based

Industry: Fruit and Vegetable Preserving and Specialty Food Mfg (NAICS 3114)

NAICS process:

311411 Frozen Fruit and Vegetables

311421 Canned Fruit and Vegetables

311422 Canned Specialty Products

311423 Dried and Dehydrated Products

Process Brief: Fruits and vegetables are scalded or briefly boiled prior to canning or freezing. Potatoes and french fries are blanched before frying to keep them from turning brown.

Energy source: Hot water

Energy Intensity: 300-400 Btu/lb of fruit or vegetable

Blanching is the rapid heating of fruits or vegetables to stop the enzyme action that causes deterioration of flavor, texture, and nutrients. Typical tubular blanchers are convoluted stainless steel pipes that are several inches in diameter and hundreds of feet in length that blanch fruits and vegetables in a continuous process. Product and water are pumped through the system where the temperature of the water and duration in the system determine the degree of blanching in the system. The product is added to the holding tank where it is preheated by recirculated water. After the product and water are pumped into the blancher, steam is injected. At the end of the blancher, a sieve separates the product from the hot water. One or more steam injection ports deliver the thermal energy to the tubular blancher and the steam contributes to the water flow. After injection, most of the steam condenses and becomes part of the water flow. One source of thermal losses is the venting of excess steam.

Water-based systems are commonly used for blanching fruits and vegetables and typical efficiencies are 30-40%. In tubular systems, the ratio of water to product is about 10 to 1 so most of the energy is used to heat water not product. Recirculation of water recovers some of this energy. In a typical application using lima beans, the tubular system is 1600 feet in length with a system retention time of 6.8 minutes. The temperature of the lima beans is raised from 65°F in the holding tank to 175°F in the blanching zone before cooling to 104°F when sieved.

|

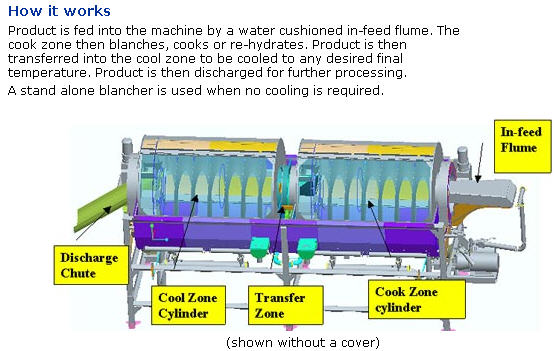

Source: http://www.lycomfg.com/howitworks4.htm |

|

Energy Efficiency

Manufacturers

FMC FoodTech Chicago

200 East Randolph

Chicago, IL 60601

Telephone: 312-861-6000

Web site: www.fmctechnologies.com

Lyco Manufacturing Inc.

P.O. Box 31

115 Commercial Drive

Columbus, WI 53925

Telephone: 920-623-4152

Web site: www.lycomfg.com

Heat and Control

Corporate Headquarters

21121 Cabot Blvd.

Hayward, California 94545-1132

Telephone: 800-227-5980, 510-259-0500

Web site: www.heatandcontrol.com