Spray Driers – Continuous, Solid, Not Heat Sensitive

Spray Driers – Continuous, Solid, Not Heat Sensitive

Industry: Fruit and Vegetable Preserving and Specialty Food Mfg (NAICS 3114) Dairy (NAICS 3115)

NAICS process:

311423 Dried and Dehydrated Products

311514 Dry, Condensed and Evaporated Dairy Products

Process Brief: Removes moisture by spraying product into a stream of heated air.

Energy source: Steam, Natural gas

Energy Intensity: 1,520-3,000 Btu/lb of water in the product

Spray driers are effective for removing the moisture from many liquid or slurry feeds, such as in the production of powdered milk, instant coffee, and cornstarch. In a typical installation, the product is atomized to produce a very fine mist. The mist is directed into a stream of hot gases that evaporate the moisture, allowing the dried solids to be separated from the gas stream. The hot gases can be produced by a natural gas furnace or by indirect heating from steam tubes. Atomization of the product can be achieved by pumping it through an orifice but increased equipment life is achieved by using a centrifugal atomizer in which the liquid is fed onto a rapidly rotating disc that generates a high quality mist. Cyclone collectors are used to separate the dried product from the gas stream.

Spray driers are useful in the industry because they produce a dried product that is highly uniform and uniformly powdered. Also, the process can deliver a high rate of production with process times of 10 seconds or less. One limitation is that the product must have sufficient moisture content to be pumped. Conveyor/band driers and fluidized bed driers can dry products with lower initial moisture contents while using less energy than the spray dryer.

Spray Drying Systems

The essential elements of the spray dryer: atomizer, air disperser, drying chamber, inlet and exhaust air handling are combined into a system that meets individual operational safety, environmental protection, and powder handling requirements. All spray drying systems can be provided with post-treatment equipment: fluid bed dryer/cooler, agglomerator, de-duster and conveyor.

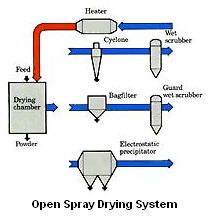

Open Spray Drying Systems

Open Spray Drying Systems

Featuring once-through airflow with exhaust to atmosphere. The majority of industrial spray drying systems handle aqueous feedstocks and use this system. Both direct and indirect air heating are applicable. Exhaust air cleaning in cyclones, bag filters, electrostatic precipitators, and scrubbers.

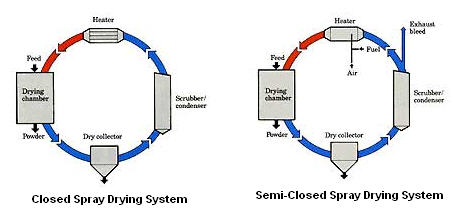

Closed Spray Drying Systems

Featuring drying in an inert gas atmosphere where nitrogen recycles within the dryer. This system must be used for the spray drying of feedstocks containing organic solvents or where the product must not contact oxygen during drying. Closed cycle plants are gas and powder tight, and are designed to the strictest safety standards. The inflammable solvent vapours are fully recovered in liquid form.

Semi-Closed Spray Drying System

Featuring either the partial recycle mode (recycle of up to 60% of the exhaust air as inlet air to the dryer, for effective waste heat utilization) or the self-inertizing mode, where direct air heating and a minimal air bleed create the low oxygen atmosphere necessary for drying aqueous feedstocks that form explosive powder-air mixtures. If odour is generated during drying, the small volumes of air vented from the system can be effectively and economically incinerated.

Aseptic Spray Drying System

Featuring sterile feed atomization and air filtering systems. These dryers are used where any form of powder contamination must be avoided. They are fabricated to special standards of finish and operate under a slight pressure. Fully automatic cleaning and sterilization systems are available. Plant layout is integrated with the laminar flow packing room.

Manufacturers

Niro Inc.

9165 Rumsey Road

Columbia, MD 21045

Telephone: 410-997-8700

Web site: www.niroinc.com

Swenson Technology, Inc.

26000 Whiting Way

Monee, IL 60449-8060 USA

Telephone: 708-587-2300

Web site: www.swensontechnology.com