Introduction

Introduction

Low-pressure steam exhaust from industrial operations such as evaporators or cookers is usually vented to the atmosphere or condensed in a cooling tower. Simultaneously, other plant operations may require intermediate-pressure steam at 20 to 50 pounds per square inch gauge (psig). Instead of letting down high pressure steam across a throttling valve to meet these needs, low-pressure waste steam can be mechanically compressed or boosted to a higher pressure so that it can be reused.

Vapor recompression relies upon a mechanical compressor or steam jet ejector to increase the temperature of the latent heat in steam to render it usable for process duties. Recompression typically requires only 5% to 10% of the energy required to raise an equivalent amount of steam in a boiler.

MVR = Mechanical Vapor Recompression uses a compressor and drive to compress the vapor, much like any air or natural gas compressor.

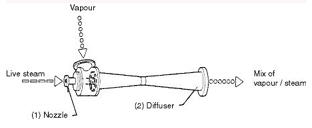

TVR = Thermal Vapor Recompression uses a sonic nozzle jet and high pressure steam to recompress a lower pressure steam/vapor. In the live steam nozzle (1) the pressure of the in-flowing steam is converted into velocity. A jet is created which draws in the low pressure vapor. In the diffuser (2) a fast flowing mixture of live steam and vapors is formed, the speed of which is converted into pressure (temperature increase) by deceleration.

TVR = Thermal Vapor Recompression uses a sonic nozzle jet and high pressure steam to recompress a lower pressure steam/vapor. In the live steam nozzle (1) the pressure of the in-flowing steam is converted into velocity. A jet is created which draws in the low pressure vapor. In the diffuser (2) a fast flowing mixture of live steam and vapors is formed, the speed of which is converted into pressure (temperature increase) by deceleration.

Operation

Example

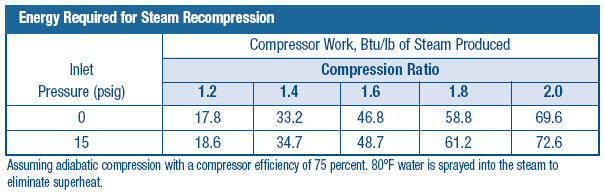

Consider a petrochemical plant that vents 15-psig steam to the atmosphere. At the same time, a process imposes a continuous requirement on the boiler for 5,000 lbs/hr of 40-psig steam. If 15-psig waste steam is recompressed to 40 psig by an electrically driven compressor, the compression ratio is:

Compression Ratio = (40 + 14.7) / (15 + 14.7) = 1.84

From the table above, the compressor requires 63.5 BTU/lb of delivered steam.

Assuming that electricity is priced at $0.05/kWh, the annual cost of driving the compressor is:

Compressor = 63.5 BTU/lb x 5,000 lbs/hr x 8,760 hrs/yr x $0.05/kWh / 3413 BTU/kWh Operating Cost = $40,745/year

If an equivalent quantity of 40-psig steam (enthalpy for saturated steam is 1176 Btu/lb) were to be supplied by an 82% efficient natural-gas-fired boiler, the steam production costs with fuel priced at $4.50/MMBTU and 70°F feedwater (enthalpy is 38 BTU/lb), are:

Steam = 5,000 lbs/year x (1176-38 BTU/lb) x 8,760 hrs/yr x $4.50/MMBTU / 0.82 Production Costs = $273,536/year

Annual Vapor Recompression Cost Savings = $273,536 – $40,745 = $232,791

More Information

Mechanical Recompression:

http://www.swensontechnology.com/mechrecomp2.html

Thermal Recompression:

http://www.swensontechnology.com/therrecomp.html

Source: DOE ITP ‘Improving Steam System Performance – a Sourcebook for Industry’ Tip Sheet 11 DOE/GO-102004-1868, October 2004; photo of GE vapor compressor system from http://www.gepower.com/prod_serv/products/compressors/en/downloads/ac_pos_displ_compr.pdf 3/2005; image and explanation of TVR from http://www.niro.com/ndk_website/niro/cmsdoc.nsf/WebDoc/ndkw5y4bwzLibrary 3/2005;