Rising Film Tubular – Tubular Evaporation – Steam-Based

Industry: Fruit and Vegetables (NAICS 3114) Dairy (NAICS 3115)

NAICS process:

311411 Frozen Fruit and Vegetables

311421 Canned Fruit and Vegetables

311514 Evaporated and Condensed Milk

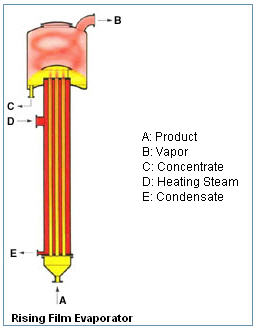

Process Brief: Water is removed by using vacuum to draw condensate and water vapor upward inside a tube that is heated by steam on the outside.

Energy source: Steam/natural gas

Energy Intensity:

Energy Intensity:

Rising film tubular concentrators were the first “modern” evaporators, coming into use in the early 20th century. The rising film principle uses a vertical tube with steam condensing on the outside surface, which transfers heat to the inside of the tube. The fluid in the tube boils, creating a vapor core in the tube. The fluid rises, causing more vapor to form. This vapor flow increases and pushes more liquid to the walls of the tube. The thin layer of liquid on the walls is more rapidly heated, accelerating the evaporation and upward flow of the vapors. Rising film concentrators are very energy efficient and achieve high throughput rates. The short cycle times of this technology help maintain good product quality. Rising film tubular concentrators are used for dairy products and typical throughputs are in the range of 30,000 pounds per hour.

http://www.swensontechnology.com/fig5.html

Manufacturers

Niro Inc.

9165 Rumsey Road

Columbia, MD 21045

Telephone: 410-997-8700

Web site: www.niroinc.com

Swenson Technology, Inc.

26000 Whiting Way

Monee, IL 60449-8060 USA

Telephone: 708-587-2300

Web site: www.swensontechnology.com