System – Rendering, Steam-based, Batch/Continuous

System – Rendering, Steam-based, Batch/Continuous

Industry: Animal Slaughtering and Processing (NAICS 3116)

NAICS process:

311613 Rendering or Meat By-processing

Process Brief: Material from the slaughter of beef, pork, and poultry is cooked to produce meat meal, bone meal, and oils.

Energy source: Steam

Energy Intensity: 442 Btu/lb of material input for all rendering process

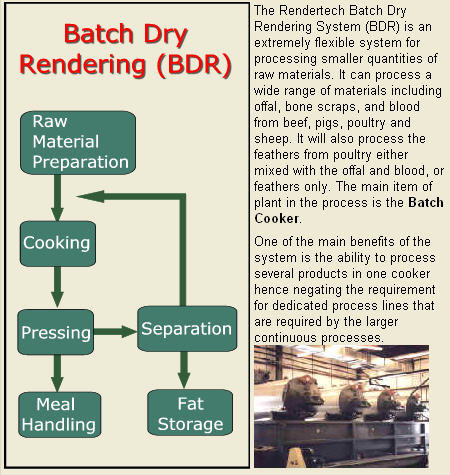

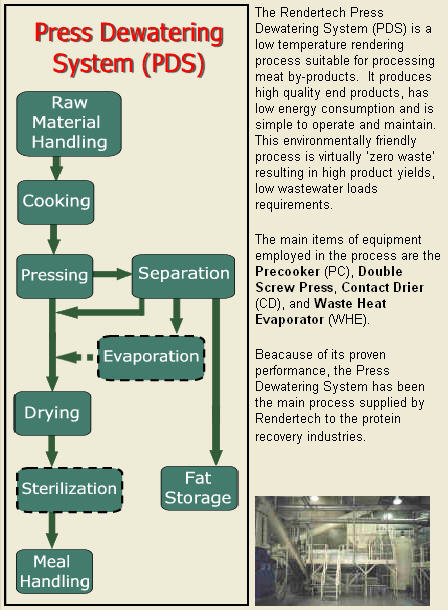

Dry Batch

The Dry Batch System is one type of cooker used by the rendering industry. The Dry Batch System uses steam-jacketed walls to transfer heat to the material. The system is “dry” because the steam does not come into direct contact with the rendered material. Some models use an agitator to enhance processing and this agitator also may be steam-jacketed. Dry Batch Cookers are used by smaller and older rendering operations. This technology was very common until the 1960s when larger, more efficient systems became the industry standard.

The waters and oils are separated released from the cooker and the solid material is removed for further processing, including pressing and grinding. A typical Dry Batch System will heat the material to 280°F for several hours at three atmospheres of pressure, although some units do not use pressurization. During a typical cycle most of the energy is required to boil the water, which is vented as steam. After the water is removed, the temperature is raised to break down the animal tissues and release the fat as tallow, which is drained off. At the end of a cycle, the remaining solids are removed for use as meat and bone meal.

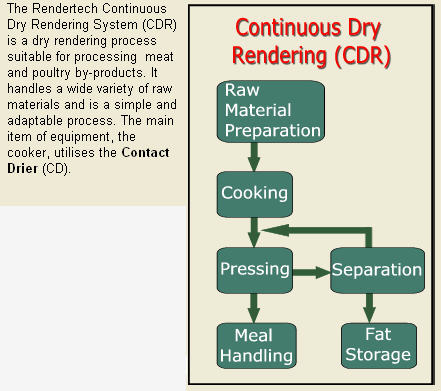

Dry Continuous

The process cycle for a continuous dry system is similar to a dry batch system. The main difference is that the process is made continuous by using a cooker design incorporating a screw or rotating drum to move the material through the cooker. A typical cooker is a steam-jacketed horizontal cylinder in which the material is constantly being turned; resulting is shorter cycle times than batch systems.

The cooker is designed with different zones to facilitate the evaporation of water and the breakdown of animal tissues. Some designs include a steam-jacketed agitator. The typical process temperature is 280°F and cycle times are two hours or less. Operating the system under vacuum enhances removal of water. Continuous cookers have replaced batch cookers since their introduction in the 1960s. Throughput rates are as high as 40 tons per hour.

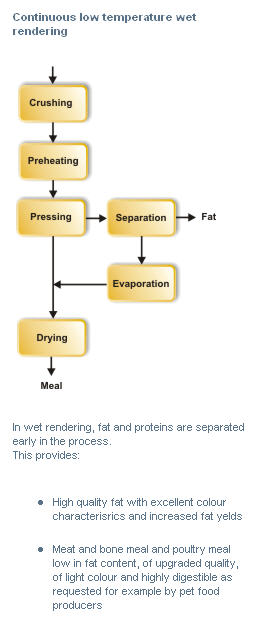

Dry Continuous Low Temperature

Continuous low-temperature systems separate the fat and moisture from material using mechanical methods. Cooking at a lower temperature (140°F – 194°F) for 10-30 minutes use as much as 75% less steam than conventional continuous systems. This cooking is not sufficient to remove moisture or to completely breakdown the animal material and additional processing is required. After cooking, the material is pressed to remove the fat and water. The remaining solids are centrifuged for additional liquid removal. The liquids are separated by skimming and filtering.

Wet Processes

Manufacturers

ANCO-EAGLIN, Inc.

120 N. Chimney Rock Road

Greensboro, NC 27409

Telephone: 336-855-7800

Web site: www.ancoeaglin.com

Atlas-Stord Denmark A/S

Islevdalvej 148

DK-2610 Rødovre

Denmark

Telephone: +45 70 27 12 14

Web site: www.atlas-stord.com

RENDERTECH LIMITED

110 Mays Road

PO Box 12 629

Penrose Auckland 1006

New Zealand

Telephone: +64 9 634 5375

Web site: www.rendertech.co.nz

The Dupps Company

548 N Cherry St

Germantown, OH 45327

Telephone: 937-855-6555

Web site: www.dupps.com/protein.html

Source: Overview GRI-03/0075; Process type graphics from http://www.rendertech.co.nz/rendering_processes.htm and http://www.atlas-stord.com/page361.aspx?recordid361=12 4/2007