Automated/Manual Hard Scalding – Birds, Batch/Continuous

Automated/Manual Hard Scalding – Birds, Batch/Continuous

Industry: Meat (NAICS 3116)

NAICS process:

Process Brief: The bird is immersed in hot water to facilitate the removal of feathers

Energy source: Hot Water/Natural Gas

Energy Intensity: 100-200 Btu/lb

Automated Scalding

Hard Scalding

Hard scalding is best for loosening feathers from the skin but degrades the skin as well. Hard scalding is performed mostly on waterfowl. The typical scalding time is 45-90 seconds at 140°F for waterfowl. Hard scalding raises the temperature of the bird’s tissues and to minimize the growth of bacteria, defeathering should be performed within 90 seconds of scalding.

Hard scalding loosens the skin, which is removed during the defeathering process. After scalding the bird is sprayed with cold water to slow the growth of bacteria. Hard scalding of chickens is performed at higher temperatures 160°F for as little as 10 seconds. This process can degrade the skin and tissue of the bird but is desirable because throughput is increased. Because the skin is removed, the use of hard scalding for chickens is limited in some markets.

Automated hard scalding is performed immersing the birds in a tank while they are hanging from an overhead conveyor. Automatic equipment speeds throughput and improves process consistency. Minimizing bacteria loads in the scalding water is a priority and maintaining consistent water temperatures is an important objective. Also, the birds entering the tank carry the most bacteria and some designs control contamination by circulating water counter to the flow of the birds. Another design uses multiple scalding tanks with birds moving from the dirtiest to cleanest tanks during the scalding process.

Medium Scalding

Medium or subscalding is most appropriate for mature chickens whose feathers are more difficult to remove than those of typical broilers or roasters. The only difference from hard scalding is the temperature and cycle time. Values for medium scalding range from 129°F -136°F for 60-120 seconds. Faster processing can be achieved by scalding at 140-145°F for 15-30 seconds.

Soft Scalding

Soft (semi) scalding is used for most broilers and roasters (chickens) and for young turkeys. The production process is similar to that used for hard or medium scalding, although production equipment is designed for high production processing of chickens. Soft scalding immerses the birds in 124°F – 130°F for 45 seconds.

Manual Scalding

Manual scalding of slaughtered birds is the immersion of the bird in a tank of hot water to loosen the feathers so that they can be more easily removed. Manual scalding is still practiced at some small facilities but has become fairly uncommon because other methods are cheaper and safer for larger operations. The dead bird is immersed in 140-150°F water for about one minute. In most cases, an open tank is used that can accommodate one to ten birds, and the water is kept hot by a burner located in the bottom of the tank. In other cases, hot water from a boiler is used to maintain the desired temperature. In either configuration, a steady flow of water helps to keep the tank cleaner. The water is changed and the tank cleaned once every shift or day.

The major advantage of manual scalding processes is low capital cost. The main problems are contamination, high labor costs, and the difficulty of achieving uniform scalding. Contamination occurs because the water circulates to all parts of the bird and the water is not changed between birds. The manual handling of the birds is expensive and operators must be very diligent to maintain consistent scalding.

Manufacturers

Dapec

PO Box 1345

884 Univeter

Canton, GA 30114

Telephone: 800-346-2177

Web site: http://www.dapec.com

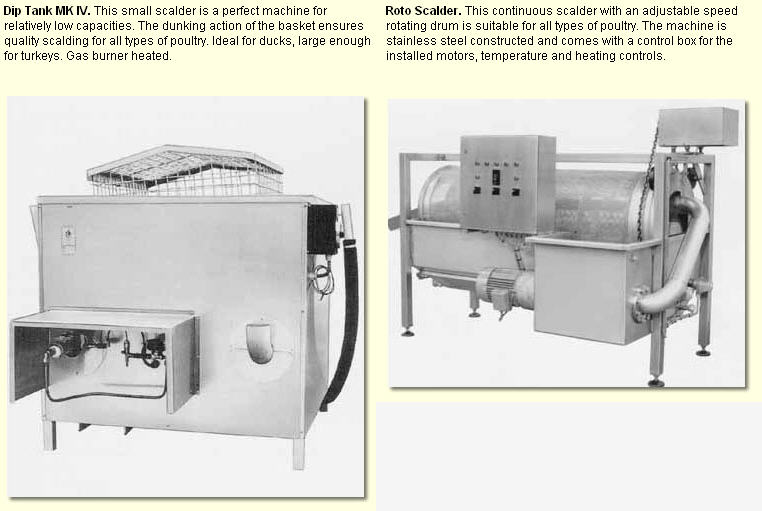

Source: Overview GRI-03/0075; Dapec scalders photos from http://www.dapec.com/products/processing/products/1_dip.html 4/2007;